Underwriters Laboratories (UL)

Underwriters Laboratories was founded in 1894 as a nonprofit independent organization testing for public safety. Specifically, the test method for Conklin roof systems is called “Tests for Fire Resistance of Roof Covering Materials” and is referenced as UL-790. This test is also utilized by the American Society for Testing and Materials and identified as ASTM E108.

Three classifications that define the fire resistance performance of a roof covering are Class A, B and C. These designations are derived from tests that measure the effect an externally-caused fire has on the roofing system. Class distinctions cover different levels of effectiveness against fires in roof-top equipment, sparks and flying embers from nearby burning buildings.

Class B roof coverings are effective against moderate fire exposures. Under such exposures, roof coverings of this class are not readily flammable, afford a moderate degree of fire protection to the roof deck, do not slip from position and are not expected to produce fling brands.

Class C roof coverings are effective against light fire exposure and afford a measurable degree of fire protection to the roof deck.

Three separate tests are conducted in the ratings:

The burning brand test measures the resistance of the roof coverings to penetration by flame. For each rating class, the brand size, the numbers of brands placed on the roof covering and the number of tests conducted differ.

The intermittent flame test subjects the samples to a cycling flame exposure. The test measures the roof covering’s ability to resist flame penetration and the reduction of this ability due to charring and cracking caused by the repeated application of flames. For each rating class, the flame temperature, duration and number of flame cycles varies.

The spread-of-flames test measures the surface burning characteristics of the roof covering. Samples are subjected to a flame and airflow test similar to the intermittent flame test, except that the flame is applied continuously.

Another Underwriters Laboratories book is entitled “Fire Resistance Directory.” Internal fire resistance is the resistance or containment performance of roof-ceiling assemblies to the upward passage of heat and flame. Also measured is their resistance to collapse from the elevated temperatures of an internal fire. The test method used is ASTM E119, also known as UL 263. The Fire Resistance Directory contains the details of assemblies with their corresponding ratings.

Both the Building Materials Directory and the Fire Resistance Directory are recommended purchases for all contractors and should be consulted for exact method of application prior to applying any Conklin roof coating or roof system assembly. Copies can be obtained by directing your request to:

Underwriters Laboratories Inc.

333 Pfingsten Road

Northbrook, IL 60062-2096

Phone: (847) 272-8800

Fax: (847) 272-8129

Factory Mutual

Over the years, Factory Mutual has established four major tests for roof coverings. There include fire, wind, hail, and weather resistance. Of these four areas of research, Factory Mutual is best known for wind uplift tests, which examine the likelihood of a roof to blow off under certain conditions. Two common classifications pertain to these tests. One is the I-60 rating, and the second is the I-90 rating. Factory Manual Publication I-28, I-29 discusses specific information on heights of building, terrain and geography, and their effects on wind uplift.

For specific information on products carrying these ratings, Factory Mutual publishes the “Approval Guide.” Copies can be obtained by directing your request to:

FM Approvals

1151 Boston-Providence Turnpike

P.O. Box 9102

Norwood, MA 02062

Phone: (781) 762-4300

Fax: (781) 762-9375

International Code Council (ICC-ES)

ICC-ES is a nonprofit, public-benefit corporation that does technical evaluations of building products, components, methods, and materials. The evaluation process culminates with the issuance of technical reports that, because they directly address the issue of code compliance, are extremely useful to both regulatory agencies and building-product manufacturers. Agencies use evaluation reports to help determine code compliance and enforce building regulations; manufacturers use reports as evidence that their products (and this is especially important if the products are new and innovative) meet code requirements and warrant regulatory approval. ICC-ES evaluation reports are public documents, available free of charge on the Web, not only to building regulators and manufacturers, but also to contractors, specifiers, architects, engineers, and anyone else with an interest in the building industry. All of these people look to ICC-ES evaluation reports for evidence that products and systems are code-compliant.

ENERGY STAR

Through its partnerships with more than 9,000 private and public sector organizations, ENERGY STAR delivers the technical information and tools that organizations and consumers need to choose energy-efficient solutions and best management practices. ENERGY STAR has successfully delivered energy and cost savings across the country, saving businesses, organizations, and consumers about $14 billion in 2006 alone. Over the past decade, ENERGY STAR has been a driving force behind the more widespread use of such technological innovations as LED traffic lights, efficient fluorescent lighting, power management systems for office equipment, and low standby energy use.

Recently, energy prices have become a hot news topic and a major concern for consumers. ENERGY STAR provides solutions. ENERGY STAR provides a trustworthy label on over fifty product categories (and thousands of models) for the home and office. These products deliver the same or better performance as comparable models while using less energy and saving money. ENERGY STAR also provides easy-to-use home and building assessment tools so that homeowners and building managers can start down the path to greater efficiency and cost savings.

Cool Roof Rating Council

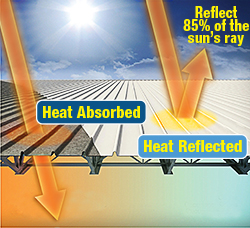

The Cool Roof Rating Council (CRRC) was created in 1998 to develop accurate and credible methods for evaluating and labeling the solar reflectance and thermal emittance (radiative properties) of roofing products and to disseminate the information to all interested parties.

The CRRC is incorporated as a non-profit educational organization for the following purposes:

- Implement and communicate fair, accurate, and credible radiative energy performance rating systems for roof surfaces.

- Support research into energy related radiative properties of roofing surfaces, including durability of those properties.

- Provide education and objective support to parties interested in understanding and comparing various roofing options

Product Rating Program

At the core of the CRRC is its Product Rating Program, in which roofing manufacturers can label various roof surface products with radiative property values rated under a strict program administered by the CRRC. Code bodies, architects, building owners, and specifiers can rely on the rating information provided in the CRRC Rated Products Directory. Which lists Conklin Company, Inc products Benchmark, Rapid Roof III, HyCrown, and Flexion. Contact Information:

Cool Roof Rating Council

1738 Excelsior Avenue

Oakland, CA 94602

Phone: (866) 465-2523 ( toll free in US ) | or (510) 485-7175

Fax: (510) 482-4421

Email: [email protected]

Florida Building Commission

The Florida Building Code became effective on October 1, 2005 and incorporates building, electric, plumbing, mechanical, and administrative codes – accessibility, energy, coastal, manufactured, and state agency codes.

When Hurricane Andrew tore apart South Florida, it exposed more than the interiors of thousands of homes and businesses. The storm also revealed a serious statewide problem: our antiquated system of locally-administered building codes and building code compliance and enforcement.

Thousands of homes and other structures simply did not stand up to the storm as well as they should have, and the effects quickly rippled out from South Florida to the rest of the state.

Andrew broke all records for insurance losses, and was the direct cause of Florida’s worst insurance crisis in history. Insurers suddenly realized that all of their worst case predictions were grossly understated – Florida was seriously underinsured and overexposed.

In the aftermath, many insurers simply pulled out of Florida and those that stayed felt it necessary to raise rates to staggering new levels in order to avoid the very real risk of sudden bankruptcy following another huge storm. Homeowners all over Florida were affected as they saw their rates rise drastically and found a lack of available new insurance threatening to pull the plug on development in every part of the state.

The secret was out. Building codes and their administration and enforcement was a statewide issue, with statewide implications. Poor compliance or enforcement in a single county could (and did) wreak havoc with homeowners, developers and commercial interests in every corner of the state.

Miami Dade County

The Miami-Dade Country Product Control Approval System was established to allow new and innovated ideas to be developed into useful, practical, lasting and safe products.

The Product Control Division receives applications, processes, reviews, and recommends to the Board of Rules and Appeals approval or denial of building construction materials, products or systems used for the protection of the building envelope. Basically limited to windows, exterior glazing, wall cladding, roofing, exterior doors, skylights, glass block, siding and shutters require approval though the issuance a Notice of Acceptance (NOA) from the Product Control Division. The high standards set by the Product Control Division is the foundation upon which they have gained a national reputation as creating the benchmark for code related approval of building systems and components.

California Title 24 Compliance

The order also directs compliance to the Green Building Action Plan, which details the measures the state will take to meet these goals. The Executive Order and Green Building Action Plan requires the CEC to:

- Develop and propose by July 2005, a simple building efficiency benchmarking system for all commercial buildings in the state.

- Develop commissioning and retro-commissioning guidelines for commercial buildings.

- Further develop and refine (Title 24) building standards applicable to commercial building sector to result in twenty percent savings by 2015 using standards adopted in 2003 as the baseline.

- Consult and collaborate with Department of General Services, Department of Finance and the PUC on a variety of other tasks.

Leadership in Energy and Environmental Design

LEED provides a roadmap for measuring and documenting success for every building type and phase of a building lifecycle. Specific LEED programs include:

- New Commercial construction and major renovation projects

- Existing building operations and maintenance

- Commercial interiors projects

- Core and shell development projects

- Homes

- Neighborhood development

- Guidelines for multiple buildings and on-campus building projects

- LEED for schools

- LEED for retail

To receive more information on each roofing system, visit Conklin Roofing Systems.