However, despite its reputation for being the leading commercial roof system on the market today, this roofing is regarded with suspicion by many building owners. That is understandable, given documented cases in which roof contractors failed to properly prep a rooftop for proper spray foam application. There are also cases in which another contractor-related problem arises: the roof contractor sometimes incorrectly applies the spray foam roof system’s surfacing layer, an elastomeric roof coating. For example, one of the most common improper applications of this roof system layer is the inconsistent application of the roof coating, or the application of it at differing levels of thickness across a rooftop.

Despite these troubles, we turn today to a notable case study (link) that shows the efficacy and benefits of this well-performing roof system.

Spray Foam Roofing in Action: Texas A&M University Case Study

That is when the physical plant team turned to spray foam systems; these systems stood out on account of their energy efficiency, easy installation, long life expectancy, and cost-efficiency. The systems were then installed over a number of buildings to stop the leaky troubles and expenses.

Almost 10 years later, efforts were taken to track the spray foam systems’ energy efficiency on 27 different on-campus buildings. The results were noteworthy, as they showed the university was able to recoup all costs of the roofing application through energy savings in an average of 4.5 years.

Building on the success stories of the spray foam applications over the BUR systems, Texas A&M University then had spray foam systems applied to its metal roofs. To this day, the university notes that the treated BUR roofs require little maintenance and upkeep and are still providing seamless, trouble-free protection. As for the treated metal roofs, on which the spray foam applications were done about 10 to 15 years ago, the university says these roofs perform as well as they did on their day of installation.

Conklin Spray Polyurethane Foam (SPF) Roofing Highlights

Need an Expert?

Our group works together to provide:

- Larger Base of Knowledge

- Group-Wide Accountability

- One Source for All Projects

- Set Standards for Service

- More Peace of Mind

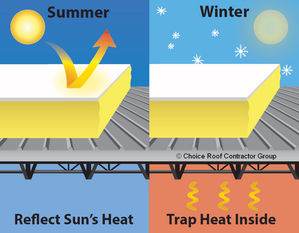

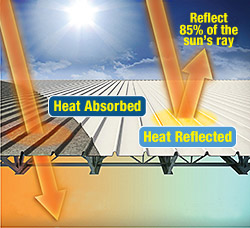

- Up to 30% cost savings on annual cooling costs

- Huge energy savings in heating and cooling year-round

- Industry’s only 18-year non-prorated warranty

- Spray foam’s energy-saving properties backed by premium-grade elastomeric coating

- Resistance against hurricane-force winds, bad hail, and other natural disasters

- Savings on avoided roof replacement costs

- Best roofing protection on the marketplace

- Greatly reduced sound transmission

Should you be interested in discussing how a Conklin SPF roof system can save you money and trouble, please call us today at 800-670-5583.

Contractors who want to learn proper application and purchase the necessary equipment should reach out to our partner Intech Equipment & Supply at 706-474-1657. They are one of the premier spray foam equipment providers in the United States with 6 full-service branches across the country. Mention Choice Roof Contractor Group for special discounted pricing.

With commercial roofing reaching up to $5.3 billion in sales in 2014, there are a lot of opportunities for roof contractors to strengthen their businesses’ competitiveness. The reputation that a contractor already has, the products that he uses, and the overall quality of his workmanship will have a strong bearing on how far his business can go in terms of growth potential.

With commercial roofing reaching up to $5.3 billion in sales in 2014, there are a lot of opportunities for roof contractors to strengthen their businesses’ competitiveness. The reputation that a contractor already has, the products that he uses, and the overall quality of his workmanship will have a strong bearing on how far his business can go in terms of growth potential. For one, all members of Choice Roof Contractor Group go to

For one, all members of Choice Roof Contractor Group go to

As a leader in the commercial roofing industry,

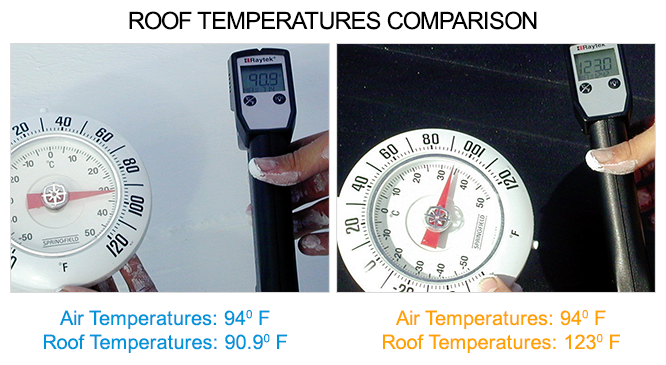

As a leader in the commercial roofing industry,  When fully applied, all Conklin roofing systems leave behind a white, highly reflective surface. These “

When fully applied, all Conklin roofing systems leave behind a white, highly reflective surface. These “

Today, we examine the power of white roof coatings and how they are saving building owners across the United States hundreds of millions of dollars in net energy savings.

Today, we examine the power of white roof coatings and how they are saving building owners across the United States hundreds of millions of dollars in net energy savings.

Even though it is the most important part of a building, a roof is hardly the first thing anyone thinks of that needs regular maintenance or inspection. But when a problem rolls around, it sure can quickly get your attention. Worse, if left untreated, even the smaller roofing defects can lead to bigger roofing problems—and expensive repair needs and more money out-of-pocket.

Even though it is the most important part of a building, a roof is hardly the first thing anyone thinks of that needs regular maintenance or inspection. But when a problem rolls around, it sure can quickly get your attention. Worse, if left untreated, even the smaller roofing defects can lead to bigger roofing problems—and expensive repair needs and more money out-of-pocket.