If you walk down the roofing supply aisle of your local home improvement store, you are bound to see a selection of aluminum coating products that promise to be effective solutions to your roofing problems. However, before you consider an aluminum coating for your commercial roof, you may want to do some homework.

Cons of Using Aluminum Roof Coatings

- Inability to Adhere — Aluminum coatings will not bond with water-based coatings. This is problematic, especially if you decide to apply a longer-lasting acrylic product in the future. A solvent-based primer can increase the chances of adhesion; however, this approach has had mixed results.

- Beware of Rain —Aluminum coatings do not provide protection against water, except for hairline cracks.

- Unable to Fluctuate — Aluminum roof coatings do not expand and contract with changing temperatures. The inflexible nature of these coatings can lead to the development of bubbles, cracks, and gaps in a commercial roof.

- Lackluster Warranties —Although warranty options may vary depending on the manufacturer, aluminum coating products typically offer a one to seven year limited warranty.

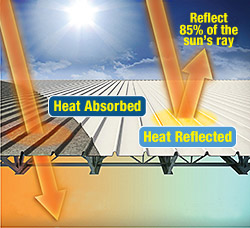

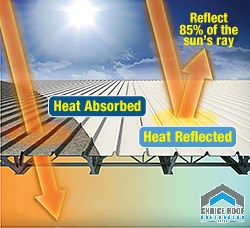

- Subpar Reflectivity — Composed of asphalt, aluminum paste, fillers, hydrocarbon solvents, and other chemicals, aluminum coatings claim to lower roof temperatures and reflect ultraviolet rays. However, according to the Cool Roof Rating Council—an organization that evaluates solar reflectance and thermal emittance—these roof coatings are 20% less efficient in solar reflectance and thermal emissivity than acrylic coatings. In as few as three years, aluminum roof coatings can be up to 50% less efficient than most acrylic coating products. For building owners, this decline translates into higher energy costs over their roof’s lifecycle. In addition, without proper UV reflectivity, a roof is vulnerable to ultraviolet degradation.

- Difficult to Clean — Cleaning is part of routine roof maintenance. But if you have an aluminum coating, cleaning can be tricky. During the cleaning process, aluminum flakes can slough off, exposing the substrate below and releasing aluminum particles into the environment.

- Apply with Caution — Because they are solvent based, aluminum coatings can have a high Volatile Organic Content (VOC), which means noxious odors are emitted during application.

- Frequent Recoating Needed — With aluminum roof coatings, be prepared to re-coat often. The product’s lifespan is approximately three to four years.

The Benefits of Conklin’s Acrylic Elastomeric Roof Coatings

Conklin coatings also meet third party standards for energy efficiency, including LEED standards, ENERY STAR® qualification, and Cool Roof Rating Council standards. They reflect up to 85% or the sun’s rays and can save owners 15% or more on annual energy costs.

Conklin elastomeric coatings have numerous other advantages:

Need an Expert?

Our group works together to provide:

- Larger Base of Knowledge

- Group-Wide Accountability

- One Source for All Projects

- Set Standards for Service

- More Peace of Mind

- Withstand hail, strong winds, heavy rains, fire, & more

- Completely restore an old roof

- Renewable, non-prorated warranty coverage for up to 18 years

- Respond to changes in outdoor temperatures

- Elastic properties allow the product to expand & contract with ease

- Fully adhered, durable, cleanable membrane

- Can add decades to the life of a pre-existing roof

- Recoatable for extended protection & renewable warranty options

- Emit fewer odors into the environment

- Preferred by hospitals & universities

- Sustainable, renewable roofing solution

It is important to note, that all roofs should be cleaned and professionally prepped before any coating is applied. Otherwise, the coating will not adhere properly and begin to peel shortly after application.

If you are looking for a reputable commercial roofing contractor, call us at (800) 670-5883. Our nationwide network of members are experienced and together can meet virtually any commercial roofing demand. When you hire a Choice Roof contractor, you can have peace of mind knowing that they are accountable to the group, can draw from a larger base of knowledge and must follow set standards for service. Contact us today! We look forward to the opportunity of earning your business.

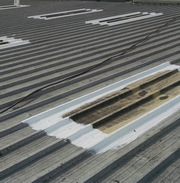

Firstly, we will address the matter you are visiting the blog post for. Metal roof repair estimates vary on the roofing project (for example, if some panels need replaced) and how much area needs to be covered. This explains why it is hard to provide a number for the cost of a metal roof repair project without a professional metal roof inspection.

Firstly, we will address the matter you are visiting the blog post for. Metal roof repair estimates vary on the roofing project (for example, if some panels need replaced) and how much area needs to be covered. This explains why it is hard to provide a number for the cost of a metal roof repair project without a professional metal roof inspection.  Our group’s preferred metal roof repair solution doesn’t cause any damage and involves no intensive procedures for your roof. This means it is minimally disruptive which leaves you stress free and at peace. With the help of Conklin’s roofing products, we are able to bring you the highest quality solutions available.

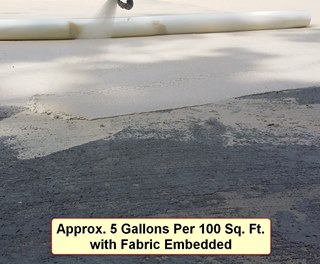

Our group’s preferred metal roof repair solution doesn’t cause any damage and involves no intensive procedures for your roof. This means it is minimally disruptive which leaves you stress free and at peace. With the help of Conklin’s roofing products, we are able to bring you the highest quality solutions available.  We start the process off by preparing your roof for the base coat. Your metal roof will be cleaned in detail from end to end and will use Conklin® Rust Off while pressure washing. While cleaning, we will also be on the lookout for loose sealant and remove obstacles such as seams, transitions, vents, curbs, and protrusions.

We start the process off by preparing your roof for the base coat. Your metal roof will be cleaned in detail from end to end and will use Conklin® Rust Off while pressure washing. While cleaning, we will also be on the lookout for loose sealant and remove obstacles such as seams, transitions, vents, curbs, and protrusions.  • Up to 18-yeat non-prorated warranty

• Up to 18-yeat non-prorated warranty For decades roof coatings have been an effective repair option for a variety of roofing substrates. They are durable, economical, and if applied properly, they can transform a troubled roof into an energy-efficient, leak-free asset. However, before executing a roof coating project, it is important to conduct a comprehensive inspection of the pre-existing roof to determine its overall condition. If any surface areas are compromised, the coating may not fully adhere and merely exacerbate a serious underlying problem.

For decades roof coatings have been an effective repair option for a variety of roofing substrates. They are durable, economical, and if applied properly, they can transform a troubled roof into an energy-efficient, leak-free asset. However, before executing a roof coating project, it is important to conduct a comprehensive inspection of the pre-existing roof to determine its overall condition. If any surface areas are compromised, the coating may not fully adhere and merely exacerbate a serious underlying problem. When coatings are applied over moisture trapped areas, the following issues can ensue:

When coatings are applied over moisture trapped areas, the following issues can ensue: The best way to identify trapped moisture is by performing a thermal scan. Utilizing infrared technology, roofing specialists can detect areas of moisture that are invisible to the naked eye. Here is how the device works: During the day the sun’s rays warm the roof and at night the roof radiates that heat back into the atmosphere, a process called radiational cooling. When insulation is wet, it retains heat for a longer period of time. Infrared imagers reveal this uneven heat dissipation and accurately pinpoint pockets of moisture. Once located, the saturated materials can be removed and the area rebuilt using dry insulation board stock.

The best way to identify trapped moisture is by performing a thermal scan. Utilizing infrared technology, roofing specialists can detect areas of moisture that are invisible to the naked eye. Here is how the device works: During the day the sun’s rays warm the roof and at night the roof radiates that heat back into the atmosphere, a process called radiational cooling. When insulation is wet, it retains heat for a longer period of time. Infrared imagers reveal this uneven heat dissipation and accurately pinpoint pockets of moisture. Once located, the saturated materials can be removed and the area rebuilt using dry insulation board stock.

While there are many coating products on the market today, Conklin’s acrylic roof coating systems standout for a number of reasons:

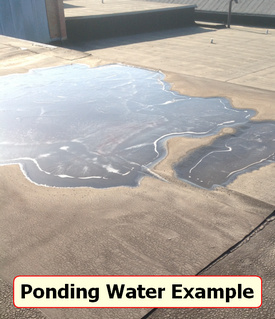

While there are many coating products on the market today, Conklin’s acrylic roof coating systems standout for a number of reasons: Regardless of the formula, roof coatings should never be an excuse to ignore ponding water issues. Every roof needs positive drainage, which means water should flow off the roof within 48 hours. When water pools for longer periods of time, it can indicate a serious problem. A roof inspection should reveal blocked drainage, depressions in the roof, structural issues, or a lack of pitch. Once diagnosed, the problematic areas can be properly repaired, making the roof truly ready to receive a coating system application.

Regardless of the formula, roof coatings should never be an excuse to ignore ponding water issues. Every roof needs positive drainage, which means water should flow off the roof within 48 hours. When water pools for longer periods of time, it can indicate a serious problem. A roof inspection should reveal blocked drainage, depressions in the roof, structural issues, or a lack of pitch. Once diagnosed, the problematic areas can be properly repaired, making the roof truly ready to receive a coating system application. Approximately 6 months ago, we began rolling out a new organizational structure with higher requirements and greater benefits for our members while also clearing up expectations and setting standards for contractors who want to be supported by our nationwide group of commercial roofers.

Approximately 6 months ago, we began rolling out a new organizational structure with higher requirements and greater benefits for our members while also clearing up expectations and setting standards for contractors who want to be supported by our nationwide group of commercial roofers.  In 2014, Choice Roof Contractor Group had received a little over 100 requests for roofing projects via our lead generation service. This year saw an ample increase – more than 200 roofing leads were generated, including several leads of 100,000+ square feet. In other words, our lead gen program more than doubled!

In 2014, Choice Roof Contractor Group had received a little over 100 requests for roofing projects via our lead generation service. This year saw an ample increase – more than 200 roofing leads were generated, including several leads of 100,000+ square feet. In other words, our lead gen program more than doubled! There were numerous stories of growth from members this year. With insights offered by fellow members, the group support, and assistance from partners, our members hit new levels of business success. One powerful testimony is found in the growth of Kansas City-based Midwest Roofing.

There were numerous stories of growth from members this year. With insights offered by fellow members, the group support, and assistance from partners, our members hit new levels of business success. One powerful testimony is found in the growth of Kansas City-based Midwest Roofing. As owner of Hometown Commercial Roofing, Carl Humes is committed to quality work and service. While serving customers, at times Carl had interacted with insurance claims adjusters. The experience the adjusters had with Hometown was extremely positive – not only did they praise Carl for his professionalism and courtesy, they also noted the high-caliber quality of Hometown’s workmanship.

As owner of Hometown Commercial Roofing, Carl Humes is committed to quality work and service. While serving customers, at times Carl had interacted with insurance claims adjusters. The experience the adjusters had with Hometown was extremely positive – not only did they praise Carl for his professionalism and courtesy, they also noted the high-caliber quality of Hometown’s workmanship. This year, Choice Roof Contractor Group rolled out a new addition to our nationwide platform: hosting Commercial Roofing Workshop & Forums across the United States. We held our first event at the facility of Schrock Commercial Roofing in Montana with great results. The event was hosted by group members with over 120 years of combined experience in roofing, construction, and marketing.

This year, Choice Roof Contractor Group rolled out a new addition to our nationwide platform: hosting Commercial Roofing Workshop & Forums across the United States. We held our first event at the facility of Schrock Commercial Roofing in Montana with great results. The event was hosted by group members with over 120 years of combined experience in roofing, construction, and marketing. With the group’s fast growth, members have been taking efforts to further better themselves and each other. From sharing their insights or knowledge to providing motivation or encouragement, group members propelled everyone to reach new heights. One example is found in the contractor-sharing business development calls hosted by Max Cruz of Massachusetts-based Cudeso Commercial Roofing.

With the group’s fast growth, members have been taking efforts to further better themselves and each other. From sharing their insights or knowledge to providing motivation or encouragement, group members propelled everyone to reach new heights. One example is found in the contractor-sharing business development calls hosted by Max Cruz of Massachusetts-based Cudeso Commercial Roofing. On December 16, Choice Roof Contractor Group hosted its biggest group of contractors at year-end Conklin events. It was by far the biggest group of our members to attend Conklin’s roof applicator training program and the Conklin Business Seminar.

On December 16, Choice Roof Contractor Group hosted its biggest group of contractors at year-end Conklin events. It was by far the biggest group of our members to attend Conklin’s roof applicator training program and the Conklin Business Seminar. Roof coatings are one of the fastest-growing segments of the commercial roofing marketplace. They offer a variety of great benefits: roof life extension, waterproofing, and energy cost savings. But how does a contractor sell the value of this roofing service to customers?

Roof coatings are one of the fastest-growing segments of the commercial roofing marketplace. They offer a variety of great benefits: roof life extension, waterproofing, and energy cost savings. But how does a contractor sell the value of this roofing service to customers?

Correct bad information – One point which building owners may wonder about is the “winter penalty” argument – or whether a reflective roof causes increased heating costs in the wintertime. Studies by the Oak Ridge National Laboratory in Tennessee confirm in most U.S. climates, A/C cost savings are far greater than any heating cost increases.

Correct bad information – One point which building owners may wonder about is the “winter penalty” argument – or whether a reflective roof causes increased heating costs in the wintertime. Studies by the Oak Ridge National Laboratory in Tennessee confirm in most U.S. climates, A/C cost savings are far greater than any heating cost increases. Commercial roofing involves a greater selection of materials than residential roofing. More expertise is required for handling these materials. Commercial buildings also differ heavily from residential properties in terms of their architectural features.

Commercial roofing involves a greater selection of materials than residential roofing. More expertise is required for handling these materials. Commercial buildings also differ heavily from residential properties in terms of their architectural features.  The residential market is populated with homeowners. Broadly speaking, there are many segments in the commercial marketplace. Industrial, retail, institutional, and public works are just a few.

The residential market is populated with homeowners. Broadly speaking, there are many segments in the commercial marketplace. Industrial, retail, institutional, and public works are just a few.  Unlike residential, once you’ve established a reputation as a quality contractor, you may get repeat work from the same customer. It’s not unusual for someone to manage or own more than one building. If you’re working with a property manager, they may have millions of square feet of roofing under their watch. Regional companies with multiple offices, franchise locations, or corporations with many buildings can also pose additional project opportunities.

Unlike residential, once you’ve established a reputation as a quality contractor, you may get repeat work from the same customer. It’s not unusual for someone to manage or own more than one building. If you’re working with a property manager, they may have millions of square feet of roofing under their watch. Regional companies with multiple offices, franchise locations, or corporations with many buildings can also pose additional project opportunities. It does take time to develop relationships. But in the commercial market, that networking pays off. Whether doing work for an existing connection or via a referral, there is potential for greater returns on time spent. New projects can come in the not-so-distant future or even some time down the road.

It does take time to develop relationships. But in the commercial market, that networking pays off. Whether doing work for an existing connection or via a referral, there is potential for greater returns on time spent. New projects can come in the not-so-distant future or even some time down the road. Are you thinking about expanding into commercial roofing? Or maybe you already have a foothold in the commercial roofing industry and want more business. Being part of an interconnected organization of capable, qualified commercial roofers can be highly beneficial. It’s a great foundation for increasing knowledge, networking with valuable connections, and opening new doors for project bids.

Are you thinking about expanding into commercial roofing? Or maybe you already have a foothold in the commercial roofing industry and want more business. Being part of an interconnected organization of capable, qualified commercial roofers can be highly beneficial. It’s a great foundation for increasing knowledge, networking with valuable connections, and opening new doors for project bids. • 16-year roofing veteran has achieved 200% growth since he joined group (400,000 sq. ft. vs. 200,000 sq. ft. last year)

• 16-year roofing veteran has achieved 200% growth since he joined group (400,000 sq. ft. vs. 200,000 sq. ft. last year) If you want to learn how to take your business to the next level and get hands-on experience with coatings, this Workshop & Forum is a great event to attend. Call us at (800) 670-5583 with any questions or visit our

If you want to learn how to take your business to the next level and get hands-on experience with coatings, this Workshop & Forum is a great event to attend. Call us at (800) 670-5583 with any questions or visit our