Contractor License Requirements and Their Influence in the Construction Industry

Contractor license requirements differ from state to state. However, there are a few prequalification requirements that, generally speaking, are consistent across state boundaries. Consistent standards include age requirements, the level of education required, certification of U.S. citizenship or foreign residency, company registration, documentation of other occupational licensing an applicant holds, and documentation that proves one’s identity.

Generally speaking, contractor licenses have to be renewed every two years, but this also varies from state to state. Regardless of someone’s experience in the construction industry, these contractor license requirements typically apply to four groups of applicants:

- Applicants who are new to the construction industry and looking to become more active in it

- Applicants who have experience in some sectors of the construction industry (e.g., roofing) and are looking for certification for taking on work in other sectors

- Highly experienced construction professionals who are renewing their licensing or certification because their expiration date has passed

- Construction professionals or companies that will be performing work in a state that is outside their state of business registration

For companies that are looking to do work outside their state of registration, it is important to register ahead of time so that deadlines for bids or work initiation do not creep up and cause timing issues. Having deadlines such as these overlap with the time in which a building company is getting its license can create logistical, business-related, and ethical issues.

Qualifications for Becoming a Contractor

Now, how do the basic requirements, or pre-qualifications, for becoming a contractor play out? Consider each of these factors below.- Age requirements- Many states require that an applicant be at least 18 years of age upon application. At the federal level, according to the Department of Labor the Fair Labor Standards Act, 14 is the minimum age for most non-farm work. However, some state laws are “tighter” in their restrictions and set the bar at 16 years of age or higher. The reason why age requirements for getting a contractor license are higher than minimum age labor standards is because of the degree of responsibility involved with contractor certification. Many applicants for contractor licensing are people who have grown up in the construction industry and are looking now to branch out on their own. Licensing therefore becomes not just a matter of allowing contractors to be employed, but also to start and run their own businesses.

- High school-level education or equivalent- When applying for a license, an applicant typically takes a written exam or two at some point. Many states have over 40 classifications of different contractor licenses available. The examinations for each of these licenses can be quite broad, and measure an applicant’s competency in finances, licensing and bonding, and other knowledge-intensive areas. A dedicated contractor can learn the ins-and-outs of these areas with hard work and focus. But education is a key resource in making sure that an applicant is able to understand and handle these details with competence. That is why many state laws spell out having a high school education or GED certification as one of their minimal qualifying standards.

- Evidence of legal residency or citizenship in the United States- This is a requirement that is in line with state and federal laws for employment. It is also a measure that helps cut down on legal complications when cases of liability or other workplace issues arise. A valid ID or proof of residency will therefore be required for meeting this standard.

- Documentation of other occupational licensing- This standard helps state agencies keep track of the construction sectors a building company is involved in. Documentation of other occupational licensing also helps to further solidify an applicant’s credibility. For some states, having an occupational license in another state can help speed up an applicant’s approval process. For instance, the state of California gives contractors who are licensed in Arizona, Nevada, and Utah the option of “reciprocity”, or being able to obtain a California contractor’s license without taking an exam. Reciprocity or similar options, though, may apply to only specific contractor classifications.

- Company registration with the Secretary of State office or equivalent- Business registration is another key factor of obtaining approval. Aside from the marketing benefits of having a name for one’s construction business, having the company registered with the state ensures legal compliance. It also strengthens a construction business’ credibility. There are multiple options for how a company can be structured, with different financial and legal benefits and drawbacks attached to each company structure. Check with your Secretary of State office, or the agency that handles company registration, for more information and the pros and cons of each company structuring.

- State-specific basic requirements- On top of these requirements, many states require proof of prior construction experience, a threshold for prior experience in the trade an applicant is applying for or a similar trade, bonding and criminal background checks, and reference letters from previous employers, among other things. With these requirements in place, you may have to prove that you have the financial means necessary for running a construction business, document that you do have on-the-job experience in a given trade, and show that you have personal credibility for offering services in that trade to begin with. Liability insurance, worker compensation, and other risk management plans and measures may also be required depending on the state’s laws. In some states, property insurance and other specialized insurance coverage may also be required.

After the Basic Requirements for Contractor Licensing

Why Contractors Join Our Network

- Lead Generation

- Mentorship Program

- Complete Training

- Discounted Pricing

- Marketing Support

Because the contractor licensing application process can be so detailed, it may help to get assistance. If you are interested in commercial roofing, give us a call at 800-670-5583. Be sure to ask how we assist our members and how they benefit from our exclusive platform of benefits and support.

Be sure to check out our e-book about making it big in commercial roofing, too.

Today we briefly examine a couple of common pros and cons of commercial roof replacement and roof coatings.

Today we briefly examine a couple of common pros and cons of commercial roof replacement and roof coatings.

Our

Our

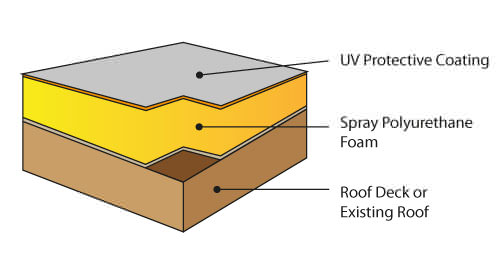

Despite all of the myths out there, spray foam roofing remains a top choice for reliable, lasting roof protection. Roof contractors and building owners each benefit from it.

Despite all of the myths out there, spray foam roofing remains a top choice for reliable, lasting roof protection. Roof contractors and building owners each benefit from it. We covered the

We covered the

Today we build on prior blog posts about

Today we build on prior blog posts about

One such brand is

One such brand is  Today we build on top of our blog post about “

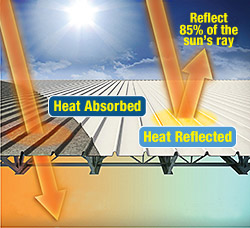

Today we build on top of our blog post about “ For a product or building to be qualified for the ENERGY STAR® logo, it must meet EPA-implement third party testing and certification. The ENERGY STAR® program makes use of testing, third party review, and compliance screening for strengthening consumer trust of qualified products and buildings meeting high energy-saving requirements. Generally speaking, the program breaks down products and buildings into four categories, with products having its own “Products” category and buildings being broken down into “New Homes”, “Commercial Buildings”, and “Industrial Plants” categories. Over 4.5 billion qualified products have been sold in the program’s 20 years of existence, and at present over 1.4 million new homes and over 20,000 facilities have the program’s blue logo.

For a product or building to be qualified for the ENERGY STAR® logo, it must meet EPA-implement third party testing and certification. The ENERGY STAR® program makes use of testing, third party review, and compliance screening for strengthening consumer trust of qualified products and buildings meeting high energy-saving requirements. Generally speaking, the program breaks down products and buildings into four categories, with products having its own “Products” category and buildings being broken down into “New Homes”, “Commercial Buildings”, and “Industrial Plants” categories. Over 4.5 billion qualified products have been sold in the program’s 20 years of existence, and at present over 1.4 million new homes and over 20,000 facilities have the program’s blue logo. Should you be interested in learning how a Conklin roof system can benefit your needs, give us a call. Be sure to ask about the commercial roofing industry’s only

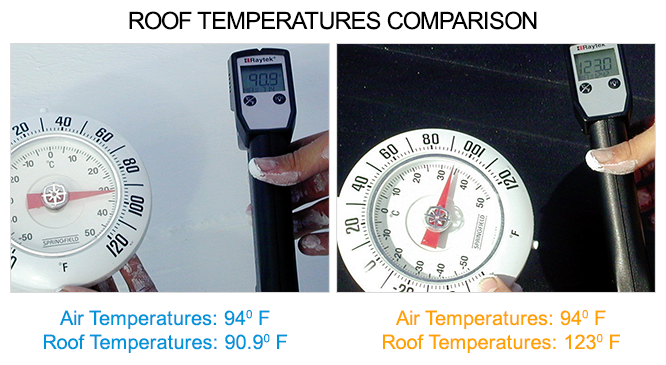

Should you be interested in learning how a Conklin roof system can benefit your needs, give us a call. Be sure to ask about the commercial roofing industry’s only  Over time, all roofs experience wear-and-tear or aging. Prolonged exposure to the sun, inclement weather such as heavy rainstorms, leaks forming from water infiltration between seams—these are just a few of the many factors that take their toll on a roof. When problems with a roof arise—even small ones—they demand a prompt response.

Over time, all roofs experience wear-and-tear or aging. Prolonged exposure to the sun, inclement weather such as heavy rainstorms, leaks forming from water infiltration between seams—these are just a few of the many factors that take their toll on a roof. When problems with a roof arise—even small ones—they demand a prompt response.