Today’s blog post will be of interest to both building owners and roofing contractors. We discuss the pros and cons of an increasingly popular commercial roofing system, a spray polyurethane foam roof, and get helpful information from a contractor’s perspective.

Today’s blog post will be of interest to both building owners and roofing contractors. We discuss the pros and cons of an increasingly popular commercial roofing system, a spray polyurethane foam roof, and get helpful information from a contractor’s perspective.

In previous posts, we have weighed the benefits of spray foam roofing and some common misnomers about commercial spray foam roofing. But what if we just consider the pros and cons of this roofing system? A certified and experienced spray foam roofing contractor weighed in with his thoughts this week and offered some guidance on the merits and downsides of this roof system type.

To frame this discussion, it is important to note that spray polyurethane foam product is being integrated with Conklin commercial roof coatings for a comprehensive roof system here. It is also important to note how these integrations have led to differently-composed roof systems.

Spray Foam Roofing Systems Integration

- Spray polyurethane foam with one coat of a Conklin roof coating product system

- Spray polyurethane foam with a base coat of roof coating product followed by a top coat

- Spray polyurethane foam with a base coat of roof coating product, followed by Conklin fabric material and two layers of top-coat roof coating product system

The last roof system is the most powerful and potent, as it is composed of many layers of fully adhered, monolithic roof coating and spray foam product. This is the system we will be examining.

Pros of Spray Foam Roofing

- Incredible tensile strength and durability highly comparable to that offered by a multi-layered built-up roof system

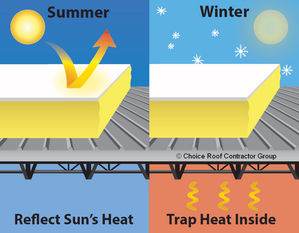

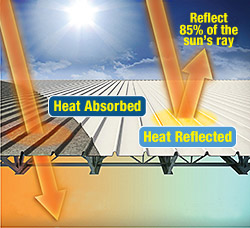

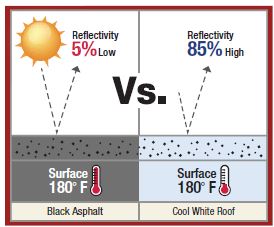

- Consumer application and value in all 50 states; the reflective top coat helps in saving on cooling costs and the SPF insulation keeps heat trapped inside during wintertime

- Potential product lifecycle of 40+ years or more, so long as the roof is properly maintained and the foam insulation is constantly protected by roof coatings

- Completely seamless, completely waterproof, and fully adhered roofing protection to the existing roof substrate on which these products have been applied

- Huge wind resistance and enhanced building structural support provided by the many layers of coating product and SPF application

- Virtually eliminates potential for water travel throughout a roof system, as punctures in the roof caused by hail or other foreign objects stay localized to just the area it affected

- SPF insulation is easily applied around protrusions, such as flashings, and around more-challenging angles up against curbs

- Capable of being applied to virtually any type of existing commercial roof system

Cons of Spray Foam Roofing

- Has to be applied with exactitude; spray foam roofing has rigorous specifications and requires steady expert hands for effective application

- From a contractor standpoint, it takes a lot of time to fully master this highly-specialized system

- Specialized training is needed so the spray polyurethane foam contractor puts down the spray polyurethane foam correctly

- Initially costlier than other roofing systems; however, it pays for itself much more quickly than even “typical” white roofing systems with the energy savings it produces

- More potential for system failure can be more present due to contractor carelessness or shoddy application, due to the exact specifications and careful application required

- Being hard to remove in some cases (however, if an old flat roof has an initial layer of 1-inch ISO board installed over it before the foam application, the foam system can be carved into squares and then removed)

It should be noted, however, that building owners will derive tremendous benefits from this system in the form of roofing protection and huge energy savings, among others. These drawbacks may be greatly outweighed by these two benefits alone.

Things that Cause Spray Foam Roofing Failure

Pros & Cons of Various Roofing Systems

Learn More- Bird pecking

- Shoddy spray foam application

- Unscrupulous contractors applying foam that is not dense enough (three-pound foam is needed, when some contractors apply two-pound)

- Foam being applied in temperature conditions that are not optimal or specified

- Foam being exposed to the sun

- Waiting too long to coat foam layer with roof coating product or primer layer on top

- Putting a light coat on top of spray foam layer, which quickly deteriorates

- Putting roof paint on top of spray foam layer, which will quickly leave foam exposed

- Old roof not having positive drainage, or has sitting pools of water on its surface (not good for spray foam application)

Once spray foam has been applied as a base layer, it is important for the top layers be applied within 2-12 hours after the spray foam application. Ideally, the application of the top layer of product over the foam will be done in the same day as the foam application itself.

This “built-up”, fabric-reinforced spray foam roofing system we have been looking at is thick enough where the foam will be much better protected from bird pecking. Also, there is a granular coating product available to Conklin contractors that can be combined with coating products so bird pecking is negated.

As the listed causes of spray foam roofing failure show, many instances of spray foam roofing failure can be attributed to shoddy contractor work or application. Therefore, many of these instances can be avoided by choosing an experienced, quality-minded spray foam roofing contractor to do the job.

Concluding Thoughts on Spray Foam Roof Systems

Need an Expert?

Our group works together to provide:

- Larger Base of Knowledge

- Group-Wide Accountability

- One Source for All Projects

- Set Standards for Service

- More Peace of Mind

Building owners and facility managers, on the other hand, can be fully confident of this roof system’s lifecycle, ongoing benefits and performance value, and stringent protection standards. All Conklin roofing systems are backed by non-prorated warranties. Plus, Conklin roofing products have been installed on over 2 billion square feet of roofing throughout the United States, and they have been a top choice in commercial roofing for over 40+ years.

Should you be interested in training with our nationwide support group, give us a call at 800-670-5583.

When asked about what drives his roofing company, Jonathan says “quality service” is the core value that’s responsible. It’s a fundamental that he’s displayed over the years, as he’s risen from a construction crew member in the family business to a forward-thinking company owner.

When asked about what drives his roofing company, Jonathan says “quality service” is the core value that’s responsible. It’s a fundamental that he’s displayed over the years, as he’s risen from a construction crew member in the family business to a forward-thinking company owner. At Conklin’s training seminar, Jonathan received hands-on experience with Conklin’s high-performance roofing systems, which built on top of his honed expertise as a construction professional. When asked about the quality of

At Conklin’s training seminar, Jonathan received hands-on experience with Conklin’s high-performance roofing systems, which built on top of his honed expertise as a construction professional. When asked about the quality of  Today’s blog post is of particular interest to building owners and facility managers, as it provides an overview of the energy-saving potential of white roofs. Other posts have examined the

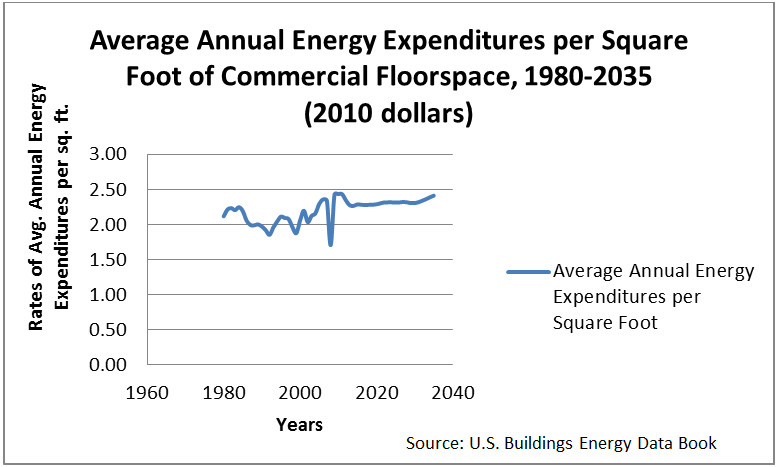

Today’s blog post is of particular interest to building owners and facility managers, as it provides an overview of the energy-saving potential of white roofs. Other posts have examined the

Some people have said white roof coatings may suffer from a “winter penalty”, or a period during the winter in which they reflect useful heat from a building and make the building use more energy for keeping its interior warm.

Some people have said white roof coatings may suffer from a “winter penalty”, or a period during the winter in which they reflect useful heat from a building and make the building use more energy for keeping its interior warm. When it comes to building a business or enhancing your bottom line with a new service offering, the most important thing to keep in mind is not “starting big”, but rather just “getting started”. It’s easy to see a big enterprise as requiring action that’s also big to get jumpstarted. But that action can ultimately be reduced down to a series of small steps, or things to be accomplished over time.

When it comes to building a business or enhancing your bottom line with a new service offering, the most important thing to keep in mind is not “starting big”, but rather just “getting started”. It’s easy to see a big enterprise as requiring action that’s also big to get jumpstarted. But that action can ultimately be reduced down to a series of small steps, or things to be accomplished over time. If you’re looking for a way to add

If you’re looking for a way to add  As many a businessperson can tell you, determination, hard work, strategic planning, and timely execution are key staples of any successful professional’s life. It’s clichéd, but it’s true regardless of what one’s career is, whether it’s owning a business or being an employee, and of what industry someone’s in. There’s no simply no substitute for discipline, defined purpose, or deliberative resiliency.

As many a businessperson can tell you, determination, hard work, strategic planning, and timely execution are key staples of any successful professional’s life. It’s clichéd, but it’s true regardless of what one’s career is, whether it’s owning a business or being an employee, and of what industry someone’s in. There’s no simply no substitute for discipline, defined purpose, or deliberative resiliency. The most important thing of these ways to act is their core unifying principle. To be successful, these habits must not be a part of your professional life, but throughout your life as a whole. “Practice makes perfect”, and if you put in the effort and habituate these practices into your daily life, there’s no limit to the things you can accomplish. In the commercial roofing industry, these practices become even more successful when paired with other important things to keep in mind.

The most important thing of these ways to act is their core unifying principle. To be successful, these habits must not be a part of your professional life, but throughout your life as a whole. “Practice makes perfect”, and if you put in the effort and habituate these practices into your daily life, there’s no limit to the things you can accomplish. In the commercial roofing industry, these practices become even more successful when paired with other important things to keep in mind. Today, commercial roof coatings are widely known for two properties: their energy efficiency and their roofing protection value. When applied on a roof substrate, the roof coating forms a new, seamless membrane over the old roof, shielding it from outdoor conditions and extreme weather patterns over time. Many commercial roof coatings leave behind a reflective roof surface with light coloring when they are sprayed and rolled on top of an old roof. However, one of the most popular coating options is the

Today, commercial roof coatings are widely known for two properties: their energy efficiency and their roofing protection value. When applied on a roof substrate, the roof coating forms a new, seamless membrane over the old roof, shielding it from outdoor conditions and extreme weather patterns over time. Many commercial roof coatings leave behind a reflective roof surface with light coloring when they are sprayed and rolled on top of an old roof. However, one of the most popular coating options is the  For those who want to maximize their competitive advantages in the commercial roofing industry from day one, Choice Roof Contractor Group presents all the tools and resources a driven person needs to be successful in commercial roofing. The recent example of one up-and-coming individual soon to be in our network, Derrick Taber, shows the power of what someone can do when he or she has the heart and work ethic to plunge ahead.

For those who want to maximize their competitive advantages in the commercial roofing industry from day one, Choice Roof Contractor Group presents all the tools and resources a driven person needs to be successful in commercial roofing. The recent example of one up-and-coming individual soon to be in our network, Derrick Taber, shows the power of what someone can do when he or she has the heart and work ethic to plunge ahead.

Getting started in commercial roofing can cost thousands of dollars. That is just to get the proper certification and training. Not so with Choice Roof Contractor Group. Because our nationwide network of commercial roofing specialists uses Conklin roofing products, all contractors go to Conklin’s roof systems training in order to learn proper application and be able to perform warrantied services.

Getting started in commercial roofing can cost thousands of dollars. That is just to get the proper certification and training. Not so with Choice Roof Contractor Group. Because our nationwide network of commercial roofing specialists uses Conklin roofing products, all contractors go to Conklin’s roof systems training in order to learn proper application and be able to perform warrantied services. Today’s blog post covers a line of roofing products that is being used to reduce a building’s cooling costs and improve building performance. We’re going to take a thorough look at elastomeric roof coatings.

Today’s blog post covers a line of roofing products that is being used to reduce a building’s cooling costs and improve building performance. We’re going to take a thorough look at elastomeric roof coatings. Many elastomeric coatings are acrylic-formulated coating products, or liquid-applied, water-based roof products that are completely seamless, are fully adhered, and form an elastic membrane over an existing roof when applied. When installed, many acrylic elastomeric roof coatings often produce a highly-reflective, white membrane over an existing roof.

Many elastomeric coatings are acrylic-formulated coating products, or liquid-applied, water-based roof products that are completely seamless, are fully adhered, and form an elastic membrane over an existing roof when applied. When installed, many acrylic elastomeric roof coatings often produce a highly-reflective, white membrane over an existing roof. Conklin roof coatings so appealing:

Conklin roof coatings so appealing: Today’s blog post will be of interest to building owners who are interested in learning about the cost of commercial roof maintenance.

Today’s blog post will be of interest to building owners who are interested in learning about the cost of commercial roof maintenance.

When a roof has been completely restored or replaced with a new roof system, how does someone keep the roof from having problems? The first step is to take active measures for prevention. An ongoing roof maintenance program will be essential.

When a roof has been completely restored or replaced with a new roof system, how does someone keep the roof from having problems? The first step is to take active measures for prevention. An ongoing roof maintenance program will be essential. Many facility managers and building owners have turned to commercial roof coatings for keeping their roof problems at bay. Why? When applied, a commercial roof coating product forms a completely seamless barrier over an existing roof membrane. The new roofing membrane “created” by the thick coating product is also fully adhered to the roof substrate, and it is completely waterproof. The end result is the old roof has its life extended, no expensive roof replacement costs arise, the old roof is protected against leaks and all manners of common roofing trouble, and the roofing membrane becomes energy-efficient.

Many facility managers and building owners have turned to commercial roof coatings for keeping their roof problems at bay. Why? When applied, a commercial roof coating product forms a completely seamless barrier over an existing roof membrane. The new roofing membrane “created” by the thick coating product is also fully adhered to the roof substrate, and it is completely waterproof. The end result is the old roof has its life extended, no expensive roof replacement costs arise, the old roof is protected against leaks and all manners of common roofing trouble, and the roofing membrane becomes energy-efficient. Should building owners want qualified roofing experts they can turn to,

Should building owners want qualified roofing experts they can turn to,